How it works

The terminal is the Single Point Mooring type; it has a single connection with the vessel that can rotate freely around the position of the terminal.

In short, the terminal has a fixed part that is well anchored to the seabed and a rotating part, which contains the oil transfer system; it can rotate freely in the direction of the ship when sea currents move it in various positions around the terminal.

The maximum flow rate during tanker offloading and loading is 7,000 m³/h. A crude oil tanker between 80,000 to 160,000 tons can be unloaded in 24-36 hours.

When the oil tanker calls Midia Marine Terminal, the SPM crew reaches the vessel using the terminal tugs: two hose handling tugs to connect tankers to the SPM installation and one escort tug to assist during discharging operation, used also for personal transfer to/from onboard the tanker.

The communication with the operators on board of the terminal is by mobile VHF radio contact.

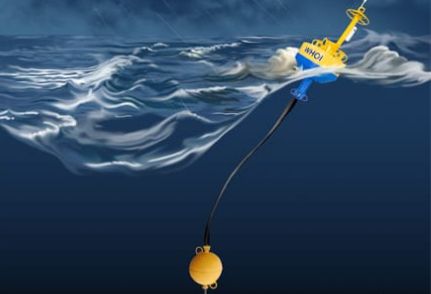

SPM Buoy control system

SPM Buoy control system comprises three independent systems that can control through telemetry the PLEM valves, instrumentation monitoring, radio communication, navigational aids.

The remote control system installed onboard the Buoy is powered using solar power system and windmills.

Apart process part, the SPM Buoy is equipped with several devices that use sensors to measure the sea state and weather conditions, giving live data that is assessed when making decisions regarding tanker vessel mooring/unmooring operations.

All the data is transmitted, displayed, interpreted and recorded using an customized software, providing exact data about:

Significant parameters are displayed in a graphical interface screen which centralizes the information, while secondary displays are showing the auxiliary parameters grouped by functionality. Alarms are provided to signal overruns of reference values.

The buoy system is a Lloyd's Class notation floating offshore facility that means that any major damage or disoperation or structural damage or modifications are to be officially reported to the Lloyd's Authority prior commencement of work activities.

Maintenance

ROV Robots

In addition to diving equipment, the terminal also uses two remote-controlled robots (ROV) for inspection.

weather

weather

underwater currents

underwater currents

swell altitude

swell altitude

orientation and position of SPM

orientation and position of SPM