People

We are committed to creating for our employees a respectful, free-from discrimination workplace where they feel included. Anti-discrimination provisions are included in the collective bargaining agreements and in the internal regulations in force.

The diversity of our people is our strength, pushing us to create our leadership model and embrace a community-centric approach to ensure competitiveness and sustainability. By digitizing operations where possible and engaging directly with our employees to foster a sense of belonging, we are continuously working to create an inclusive, dynamic, and resilient organizational culture.

All Group companies operate in full compliance with all applicable national and international laws and regulations with respect to human rights, safe working conditions, promoting fair employment conditions, responsible management of environmental issues, and high ethical standards.

All these principles are also thoroughly detailed in our Supplier Code of Conduct, which is mandatory in any supplier agreement concluded by the Group and its subsidiaries. All suppliers and their subcontractors must comply with the Group’s Supplier Code of Conduct, verify compliance by providing information to the Group, and allow access on their premises for regular assessments.

The Supplier Code of Conduct is constantly updated and improved to reflect alignment with local and international regulations, as well as any evolutions with potential impact on our activities.

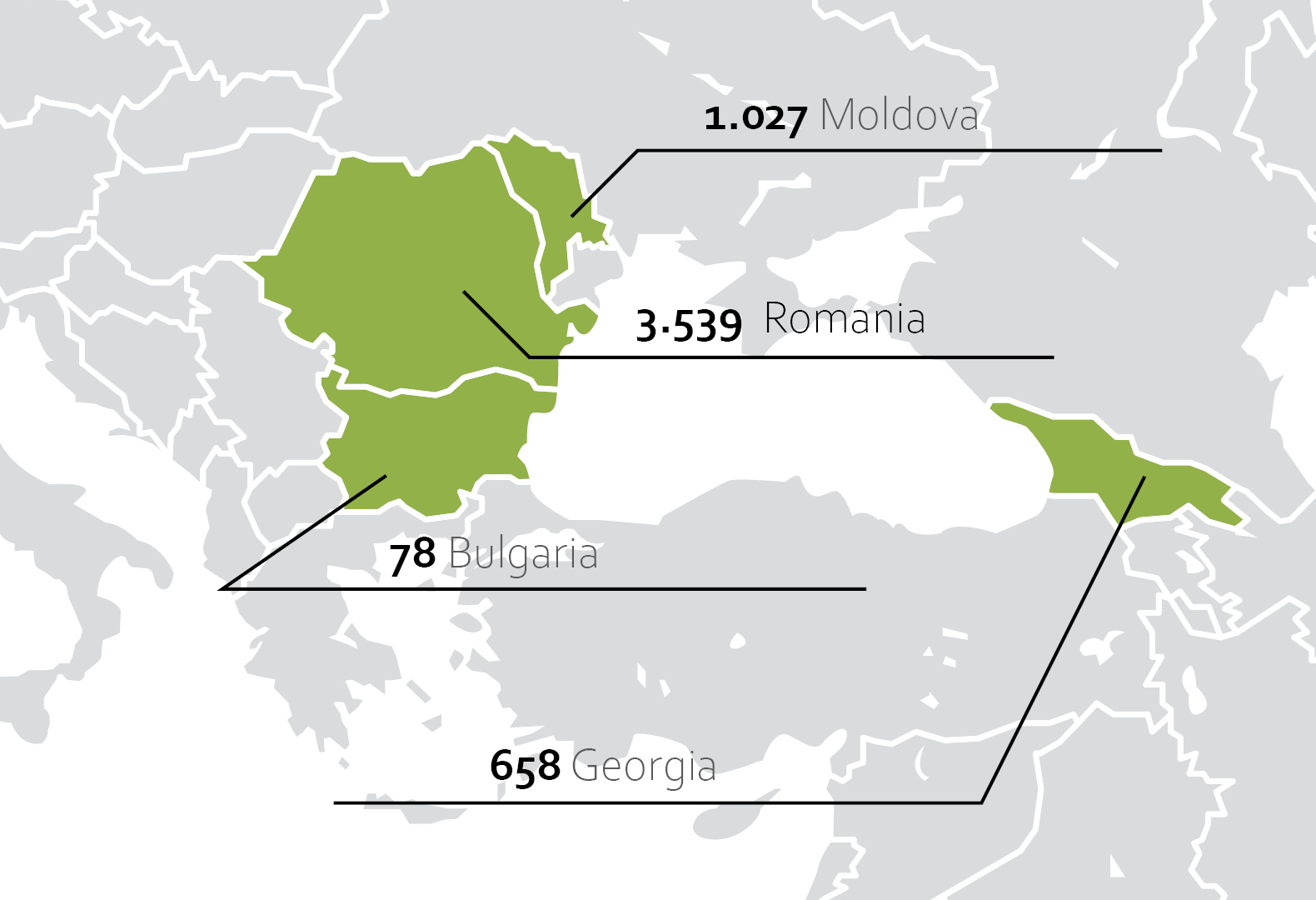

5,358 - Total number of employees in the group

- 5,358 - Total number of employees in the group

- 1,582 - Total number of female employees in the group

- 3,776 - Total number of male employees in the group

- 30% - Percentage of female employees in the group

- 70% - Percentage of male employees in the group

- a total of 89,423 training hours for the workforce of 5,358 individuals as of December 31, 2023

- an average of training hours per total headcount of 16.69 (24% improvement versus last year); managers engaged in an average of 18.95 hours of training, while execution-level employees completed an average of 16.46 hours.

- In Romania, the training initiatives reached 4,986 participants, with 2,474 employees engaging in one or more training courses.

- Rompetrol Rafinare and Rompetrol Energy accounted for nearly half of the total training hours, cumulating approximately 49,000 training hours – around 50% of total training hours.

We adjusted our major skill development, professional and personal growth programs to the current digital requirements. Highly skilled and motivated employees are our best asset, each with a role to play to deliver our sustainability agenda.

Rompetrol is more than a workplace, it is a community of 5 generations of professionals.

Safety

We prioritize the safety of our employees, contractors, and communities, to ensure sustainable operations ans secirity to the people. Safety performance indicators are an essential tool for measuring and monitoring the effectiveness of our safety programs, policies and procedures.

As an industry best practice, we benchmark our main reactive indicator (LTIR – Lost Time Injury Rate) against International Oil and Gas Producers (IOGP) association. Our aim and efforts are towards LTIR 0, but considering the profile of our industry, the realistic objective and KPI for us is to be under the annual IOGP average.

The safety of our employees represents a top priority across all Group entities and operations, being a crucial part of our strategy. To ensure the safety and well-being of each employee we have been implementing and constantly updating extensive safety standards and procedures in an attempt to consolidate our “safety first” culture.

Our key objectives on the long term are:

Our commitment to safety extends beyond our employees, to our partners and suppliers, our customers, and the communities in which we carry out our activities. Our risk-based approach follows a clear set of standards aligned with national and international regulatory requirements. We have an integrated QHSE management system in place, which is certified against ISO 9001, ISO 14001, and ISO 45001.

The implemented Management System consists of nine distinct elements covering all the QHSE topics and professional areas. The entire KMG International workforce is under the scope of the mentioned system, including operational and non-operational employees and interns.

The Group’s various internal policies pertaining to occupational health and safety cover all types of operations carried out throughout the Group and represent the foundation of both preventive and reactive programs aimed at delivering safe, secure, and sustainable operations.

Rompetrol monitors HSE Contractor indicators, as a best practice, and to ensure that the same level of operational excellence is shared by our contractors.

For more details please see the 2023 Sustainabililty Report here.