A producer and supplier of special products

Vega has evolved from a classic refining unit to a producer and supplier of special products obtained exclusively from raw materials supplied by Petromidia. The two refineries of Rompetrol operate in an integrated system obtaining high added-value products.

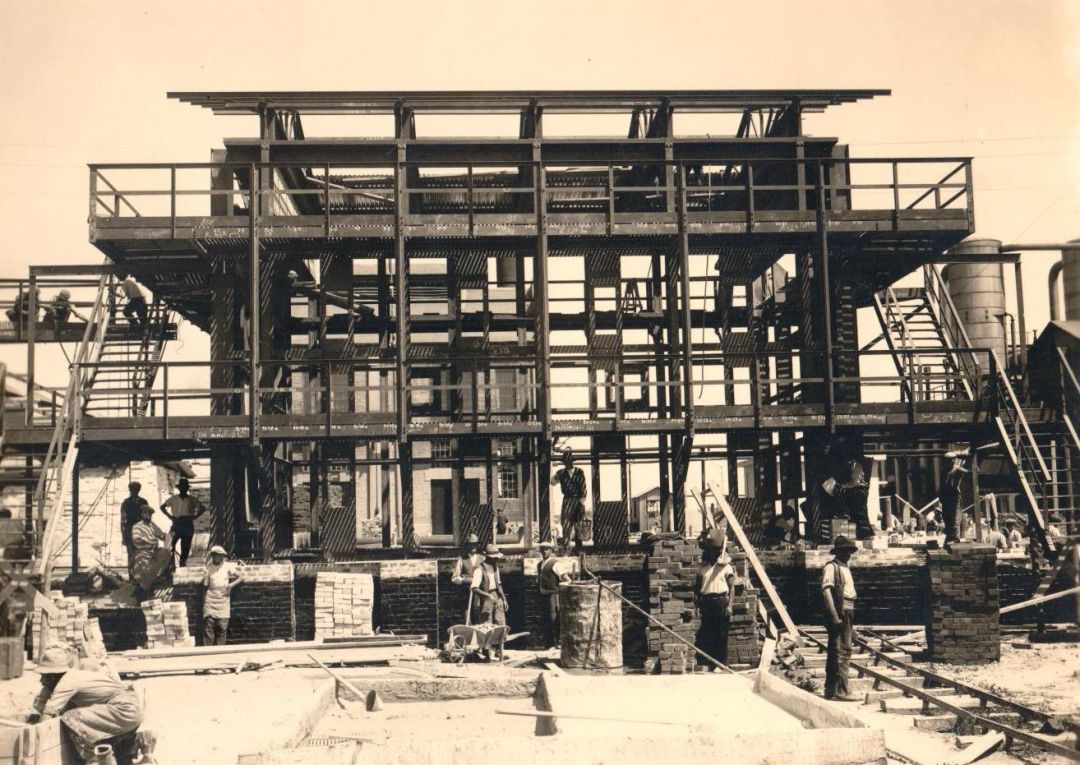

It is the most long-lasting refinery and played a complex role from its very beginning, acting as a specialized link between all 11 refineries of Romania. Built during the time of Titu Maiorescu, the refinery went through the two World Wars, but it has managed to adapt to the ever-changing environment over the years.

Vega Refinery is the sole producer of normal hexan, bitumen and refined white spirit in Romania.

Vega is the smallest refinery among all 4 refineries in Romania.

Having an installed processing capacity of 350,000 tons/year, it uses different types of raw materials from Petromidia to produce special products with a high added value: solvents, heating oils, bitumen, and additives for a variety of industries (chemical, petrochemical and rubber processing industry, food industry and others).

Projects dedicated to energy efficiency and environmental protection

In the latest years, important projects have been successfully completed at the Vega refinery, with the main role being to reduce the impact on the environment, but also to improve operational efficiency. Among the completed actions, we list:

- Modernization of fuel storage tanks;

- Automation of the vapor recovery unit;

- Modernization of the thermal power plant;

- Installation of the new technological furnace in the Vacuum Distillation installation.

All these actions have reduced the emissions of organic compounds by over 90%, increased the energy efficiency of the refinery and last but not least have contributed to increasing efficiency.

Vega – 120 Years

Tradition. Innovation. Uniqueness. Since 1905.

Established during a period when oil processing was a global first, Vega is among the pioneers of the Romanian refining sector.

A reliable community member

Vega refinery was strategically located in the north of Ploiești.At that time, it was on the outskirts of the city, which would have allowed a further expansion, in the immediate vicinity of a railway line, which connected Ploieşti and Vălenii de Munte.

The positioning next to the railway line allowed the fast transport of the products obtained from Vega to the port of Constanţa and from here to the buyers from all over the world, and this aspect was essential.

Today, next to the production unit, there is still the housing colony, a community developed during the Second World War for the refinery's employees. During the 1950s, Romania had one of the best oil and gas schools in Europe. Vega has permanently provided well-trained specialists, products and equipment all over the world, not a few being the refineries designed and built from scratch by Romanian engineers.

Lagoons Remediation

The program for remediation and greening of the historical lagoons of Vega Ploiești Refinery is a complex project and one of the largest environmental projects in Romania.

In these lagoons, acid tars and petroleum residues were produced and stored overwhelmingly in the period before the privatization of Vega Ploiesti Refinery (1905-1999 being generated by the crude oil processing methods used in the 160 years history. For example, in the 1980s, Vega was the only producer and supplier of catalysts for the domestic refining industry, and for the other 10 refineries in operation at that time.

The achievement of this comprehensive program implies not only the allotment of extraordinary financial resources but also the adoption of the best available technologies, the most rigorous safety measures and permanent cooperation with all those involved.

Read more about this project

History of lagoons

1999

62,000 tons of waste was estimated in the privatization contract

The existing volume in lagoons was at least 4 times bigger

2002-2011

Rompetrol has removed approximately 80,000 tons of waste — significantly exceeding the commitments made at the time of privatization — through a total investment of USD 17.4 million.

2022

Rompetrol completed the remediation works for the historical lagoons 18 and 17 — two of the largest within the Vega refinery — marking a significant step forward in its environmental commitment.

2024

The company finalized the tender for the remediation works of lagoons 19 and 20.

2025

The company continues the remediation works for the historical lagoons, allocating USD 20 million.

Key Figures

Results H1 2025

The Vega Ploiesti refinery, the only producer of bitumen and hexane in Romania, processed about 181 thousand tons of raw materials in H1 2025 (a 54% increase), driven by high flows of raw and semi-finished materials delivered by Petromidia.

In the first 6 months of 2025, the refinery utilization rate increased by 59.57% compared to the same period last year. The Vega refinery recorded good operational parameters, with an energy consumption of 2.65 GJ/t and a technological loss of 0.69%.

Read more about the financial and operational results in H1 2025

Results 2024

The Vega Ploiesti refinery, the only producer of bitumen and hexane in Romania, processed about 293 thousand tons of raw materials, which is below the level of the previous year, a level directly determined by the quantities of raw materials and semi-finished products received from the Petromidia refinery.

The Vega refinery recorded good operational results in areas such as energy consumption – 2.69 GJ/ton and technological consumption – 0.8%.

Read more about the financial and operational results in 2024

PETROMIDIA

One of the major sources of authority for Rompetrol Brand is Petromidia refinery, the pillar of the refining industry.